In the world of metal fabrication.There’s one thing that stands out above all else – the brilliance of sheet metal fabricators. These skilled artisans craft and mold metal into awe-inspiring creations transforming raw materials into works of art. If you’re considering becoming a sheet metal fabricator or are simply curious about the craft you’re in the right place.

1. What are Sheet Metal Fabricators?

Before we know on this journey, it’s essential to understand what sheet metal fabricators do. They are artisans who specialize in shaping, bending and joining metal to create various structures and artworks. Whether it’s crafting intricate sculptures or assembling industrial parts, sheet metal fabricators are the unsung heroes behind many metal products we encounter daily.

2. Acquire Basic Skills

The first step in your journey to becoming a sheet metal fabricator is to acquire basic metalworking skills. Start by learning how to cut, shape and join metals. This will lay a solid foundation for your future projects. Attending a trade school or finding a mentor can be an excellent way to learn these fundamental skills.

3. Choose the Right Tools

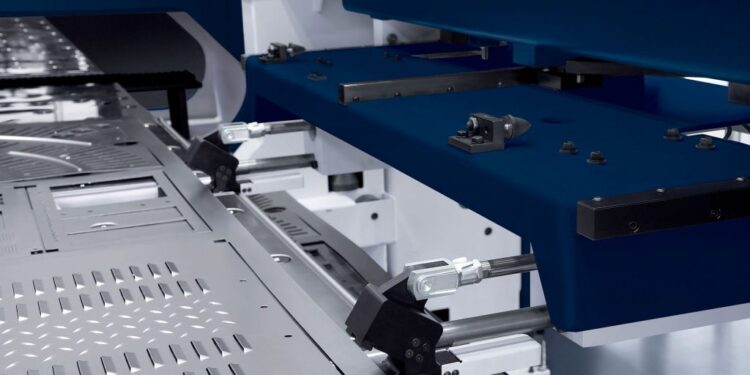

Just like a painter needs brushes and canvas. A sheet metal fabricator needs the right tools. Invest in quality equipment, such as cutting torches. Welding machines and shearing tools. Having the appropriate tools at your disposal will make your work more efficient and precise.

4. Safety First

Working with metal can be hazardous if safety precautions are not taken seriously. Make safety your top priority. Use personal protective equipment like gloves, helmets and eye protection. Ensure that your workspace is well-ventilated to avoid inhaling harmful fumes. Being safe is the first step to shining in the world of sheet metal fabrication.

5. Plan Your Projects

Creativity without structure can be chaotic. Before diving into any project take the time to plan it thoroughly. Create detailed blueprints calculate measurements and outline your steps. Having a well-thought-out plan will prevent mistakes and ensure a smooth workflow.

6. Precision is Key

Precision is what sets sheet metal fabricators near me apart from the rest. Pay attention to every detail from measurements to angles. Use precision tools to ensure that your cuts and welds are immaculate. The extra effort you put into precision will be evident in your finished pieces.

7. Master the Art of Finishing

The finishing touches make all the difference in sheet metal fabrication. Learn techniques for smoothing, polishing, and applying finishes to your creations. A well-finished product not only looks impressive but also lasts longer and is more durable.

8. Networking and Learning

To keep shining in the world of sheet metal fabrication. It’s essential to network with fellow artisans and continue learning. Join metalworking associations, attend workshops and participate in exhibitions. The more you learn and connect with others. The brighter your future in this field will be.

9. Embrace Creativity

While mastering the technical aspects is crucial, don’t forget to embrace your creativity. Allow your artistic side to flourish. Experiment with different designs and techniques. Your unique style and creative flair will make your work stand out.

Conclusion

In conclusion, sheet metal fabricators are the magicians of the metalworking world. They turn ordinary pieces of metal into extraordinary works of art and functional structures. To join their ranks, follow the seven steps outlined in this article: acquire basic skills, choose the right tools, prioritize safety, plan your projects, focus on precision, master the art of finishing, and never stop learning. With dedication and a touch of creativity. You too can shine as a sheet metal fabricator.

Thanks for visiting goseobuzz